This production represents one of the field in which the company has built up a wide experience and it can be able to guarantee reliable supply.

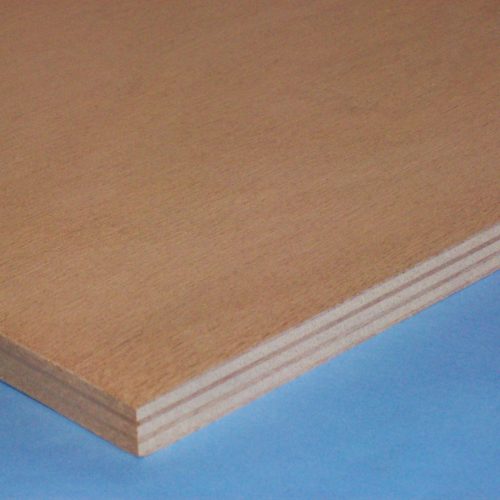

“Marine” plywood is a veneered-based panel of good durability with respect to fungal decay and bonding quality, making it suitable for the manufacturing and interior fittings of marine craft and several applications in building construction. Its durability derives from the resistance to biodegradation of the wood species used combined with the weathering performance of the bonding quality and the high number of layers.

The timbers most frequently used by Compensati TORO to produce marine plywood are Okoumé, Khaya and Sapelli. Okoumé (Aucumea klaineana) is a wood species with a resistance to biodeterioration suitable for the service and hazard classes in which marine plywood is normally employed. Khaya (Khaya sp.) and Sapelli (Entandrophragma cylindricum) are African woods belonging to the mahogany group that have a nice decorative aspect and are characterized by durability class 3 of EN 350. Panels made with the faces in mahogany veneers and inner plies of Okoumé are also available.

This type of plywood is made with selected veneers of adequate quality and lay-up. Generally face veneers are of surface appearance class II/III (complying with EN 635) while core veneers have glued edge joints.

On request, panels can be overlaid with decorative sliced veneers (for instance Teak, also in thicknesses up to 25/10 mm) or can be made with holly inlay (in white painted wood or black rubber stripes). A more economic version produced in the factory is made overlaying a basic marine plywood with a plastic laminated sheet which reproduces the surface appearance of Teak or Sapeli (generally with parallel white stripes); in this case the reverse side is balanced with a laminated sheet of light colour.

The adhesive used for bonding marine plywood is a modified MUF system that satisfies the requirements for marine applications, while the bonding quality is checked according to EN 314 after a pre-treatment that simulates a long time exposure to weathering agents that the plywood must withstand in service. The best behaviour of the panels is reached when their edges are adequately protected during use.

The marine plywood produced by Compensati TORO is conforming to the standard BS 1088-1:2003 in line with the requirements of EN 13986.